Precision Measurement

Precision Alignment and Measurement You Can Trust

True North Metrology & Alignment delivers precision measurement services and expert machine alignment for industries where accuracy directly impacts performance—like paper production, automotive manufacturing, aerospace development, chemical processing, steel fabrication, food production, and high-tolerance machining.

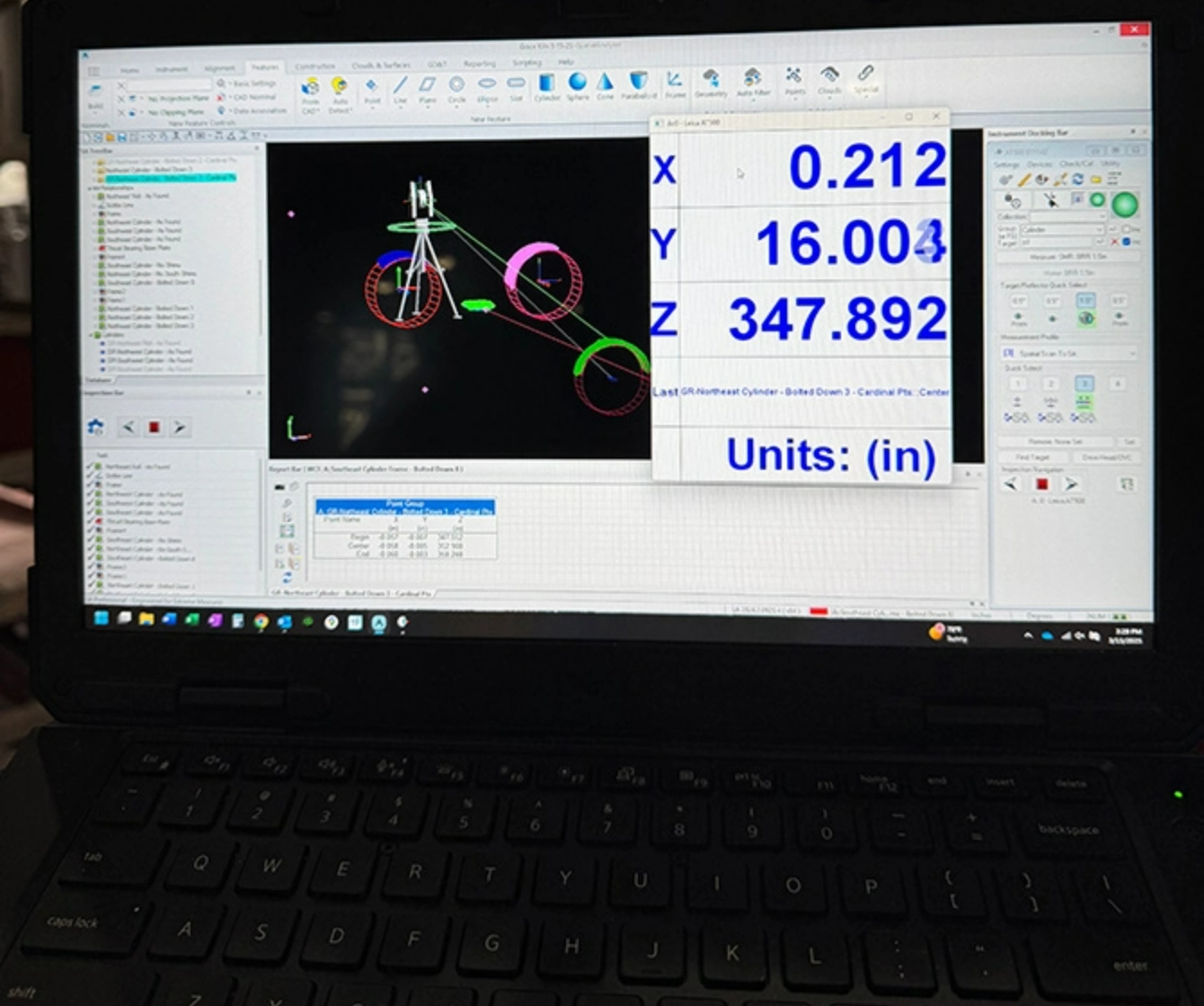

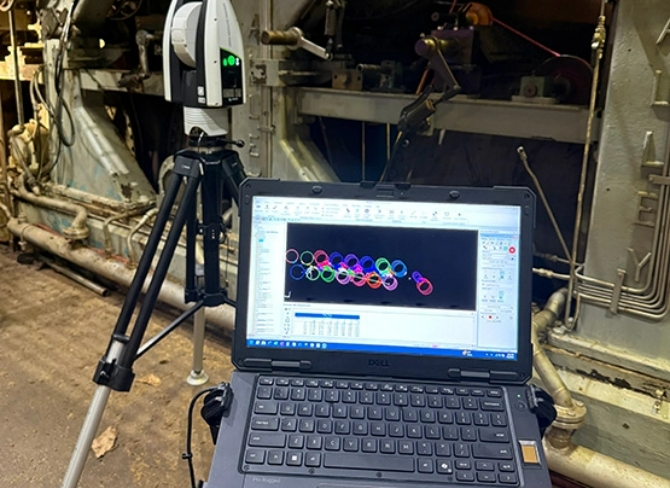

We leverage portable laser tracker systems and 3D metrology to bring cutting-edge measurement capability directly to your plant floor. This on-site approach ensures quick feedback loops, limits production interruptions, and captures the data essential for critical setups and ongoing diagnostics.

Each of our services is designed to address demanding industry requirements. By employing advanced 3D tracking, we can generate precise point-cloud data to compare manufactured parts against CAD models—helping you catch deviations early. Our baseplate elevation assessments ensure heavy equipment is level and stable, safeguarding both performance and safety. With our QC-focused verification services, we support compliance with rigorous quality standards by delivering traceable, real-time measurements. This focus on quality control not only ensures precision—it drives efficiency, reduces rework and scrap, and helps extend equipment life.

Beyond measurement, our precision alignment expertise is critical to avoiding common industrial issues like misaligned shafts, which can cause excess wear, vibration, energy drain, and unexpected downtime. Using 3D metrology software, we align rotating machinery to spec—reducing stress on components like bearings and seals, improving energy efficiency, and extending the operational lifespan of your equipment. Whether installing a new production line or maintaining critical rotating assets, our services help keep your plant running reliably, efficiently, and profitably.

Why True North?

Industries We Serve

Manufacturing

Manufacturing

Heavy Industrial

Heavy Industrial

Paper Mills

Paper Mills

Plastics Manufacturing

Plastics Manufacturing

Food Processing Plants

Food Processing Plants

Chemical Plants

Chemical Plants

Aerospace Facilities

Aerospace Facilities

Automotive Plants

Automotive Plants

Steel Mills

Steel Mills

Machine Shops

Machine Shops

Latest From Blog

Precision Equipment Setting

Industrial Equipment Alignment

What Our Customers Say