Machine Alignment

Keep Your Equipment Running True for Lasting Performance

At True North Metrology & Alignment, we offer expert machine alignment services—ensuring that rotating equipment, actuated machinery, and coupled systems run true, efficient, and free from avoidable wear.

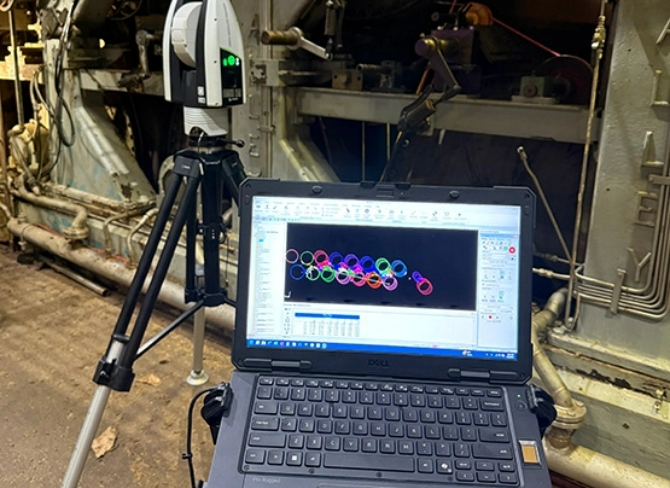

We utilize advanced laser trackers and 3D metrology software to correct offset and angular misalignment with unmatched accuracy. Whether aligning drums, rolls, shafts, couplings, belts, machine trains, or any other specialty equipment, our on-site team provides precise alignment data to ensure peak equipment performance.

Why Machine Alignment Matters

Misalignment is the hidden culprit behind over 50% of rotating machinery failures. Even slight offset or angular misalignment can lead to vibration, premature component wear, increased energy use, and unexpected downtime. Our laser alignment technology significantly reduces setup time compared to traditional methods, while delivering measurements down to a thousandth of an inch.

Our machine alignment services cover the full spectrum of rotating and coupled systems, including:

• Shaft and coupling alignment for motors, pumps, gearboxes, fans, extruders, and machine trains.

• Cold and hot alignment to account for thermal expansion and ensure true alignment at operating temperature.

• Baseplate leveling to eliminate stress points from uneven mounting surfaces.

• Verification and reporting with documented before-and-after alignment data, CAD model comparisons, and compliance-ready reports.

Each of these services directly contributes to better plant performance: improved uptime and reliability, extended life of bearings, couplings, and seals, reduced energy consumption, fewer breakdowns, and consistent product quality. Our approach not only limits unplanned downtime but also makes your facility more reliable by reducing wear and tear on equipment.

GIVE US A CALL

Industry Expertise Across Applications

True North’s alignment services support a wide range of high‑precision industries, including aerospace, automotive, paper production, metal fabrication, chemical processing, and precision machining. Whether you need machine tool calibration (e.g., lathes, mills, grinders) or heavy rotating machinery alignment, our field team delivers tailored alignment plans that reduce risk and optimize performance.

Here’s how our on‑site laser alignment workflow ensures accuracy and reliability:

• Equipment Assessment – We evaluate machine type, runtime, thermal behavior, and layout to understand the unique needs of your system.

• Initial Measurement – Using portable laser technology and 3D metrology software, we capture exact offset and angular dimensions.

• Adjustment & Realignment – We provide the data needed to make fine tuning adjustments to equipment under both cold and hot operating conditions to meet precise alignment tolerances.

• Final Verification & Reporting – We deliver detailed before‑and‑after alignment reports with CAD model comparisons and compliance‑ready data.

By combining industry-specific expertise with a proven process, we help keep your machinery running smoothly, reduce maintenance costs, and improve long‑term operational performance.

Why Choose True North?

Precision alignment is more than a service—it’s our expertise. We bring field-proven metrology tools and experience straight to your plant floor for minimal disruption and maximum data visibility. By combining laser accuracy with actionable diagnostics, we help your process run smoother, safer, and more cost‑effectively.

Industries We Serve

True North Metrology & Alignment supports a wide range of industries where precision is critical to safety, efficiency, and performance. From complex manufacturing lines to heavy industrial machinery, our team delivers top-notch measurement and alignment services that minimize downtime and maximize equipment life. Whether in paper mills, aerospace facilities, food processing plants, chemical facilities, automotive plants, steel mills, or machine shops, we tailor our solutions to meet the unique demands of each environment.

Manufacturing

Manufacturing

In fast-paced manufacturing environments, precision directly impacts equipment reliability, production metrics, and product quality. True North delivers expert measurement and alignment services that keep complex machinery running smoothly and within spec.

Heavy Industrial

Heavy Industrial

Heavy industrial systems demand extreme tolerances to avoid costly downtime and equipment wear. True North specializes in aligning large-scale machinery and structural components to ensure reliable, efficient operation under even the toughest of conditions.

Paper Mills

Paper Mills

Paper mills rely on perfectly aligned rolls, dryers, and cutter systems to maintain quality and prevent costly equipment downtime. True North’s precision measurement and alignment services are designed to keep these critical systems reliable and operating at peak performance.

Plastics Manufacturing

Plastics Manufacturing

Plastic parts are often produced at extremely high volumes, where even the smallest dimensional error in tooling or equipment alignment can result in thousands of defective parts. True North Metrology helps plastics manufacturers maintain tight tolerances across injection molding, extrusion, and thermoforming operations. Using advanced 3D laser trackers and precision measurement software, we verify mold alignment, inspect large tooling, and ensure equipment is properly calibrated for repeatable production. By identifying dimensional deviations early and optimizing machine setup, we help plastics manufacturers reduce scrap, improve part consistency, and maintain reliable, high-quality output across every production run.

Food Processing Plants

Food Processing Plants

In food production, consistent alignment ensures smooth, sanitary, and efficient operation. True North supports food processing facilities with accurate, non-invasive measurement and machine alignment solutions tailored to strict industry requirements.

Chemical Plants

Chemical Plants

Complex piping systems, pumps, and rotating equipment in chemical plants require meticulous alignment to maintain reliability, safety, and process integrity. True North provides precision measurement services that support regulatory compliance and uninterrupted performance.

Aerospace Facilities

Aerospace Facilities

In aerospace, precision isn’t optional—it’s mission critical. From aircraft assembly lines to testing facilities, True North supports aerospace operations with cutting-edge measurement and alignment services that meet the industry's highest standards. We help ensure structural accuracy, equipment reliability, and performance consistency across sensitive components and systems where even the smallest deviation can compromise safety or efficiency.

Automotive Plants

Automotive Plants

Automotive manufacturing relies on seamless production lines and tightly calibrated systems to maintain speed, safety, and quality. True North provides precision measurement and alignment solutions that support everything from stamping and welding systems to robotics and conveyor infrastructure. By keeping components in perfect sync, we help automotive plants improve reliability, reduce downtime, and maintain strict quality control standards.

Steel Mills

Steel Mills

Steel mills present some of the harshest alignment challenges. Excessive vibration and thermal growth can wreak havoc on equipment and degrade product quality. Our on-site alignment and measurement solutions help steel mills achieve proper roll, stand, and drive-train alignment—reducing downtime, improving throughput, and protecting valuable capital equipment.

Machine Shops

Machine Shops

High-tolerance machining operations demand precise calibration and alignment of machine tools. We use advanced 3D metrology software and portable laser trackers to level, square, and align lathes, mills, grinders, and other critical assets. We can also assist in the setup of large parts that are beyond the reach of typical machinist hand tools. This ensures consistent machining accuracy, reduces scrap, and enhances your shop’s ability to meet customer specifications on every project.

Latest From Blog

Explore our blog for expert insights, practical tips, and real-world applications of precision measurement and machine alignment across the industries we serve.

Metrology Case Studies

September 10, 2025

Precision Equipment Setting

True North Metrology and Alignment recently supported a capital project at a chemical facility in Southwest Louisiana. We partnered with

Read More

Metrology Case Studies

September 10, 2025

Industrial Equipment Alignment

True North Metrology and Alignment recently completed a precision measurement project at a paper mill in central Arkansas. Our team

Read More

What Our Customers Say

Our commitment to quality and care shows in every review. Explore what makes us one of the top-rated teams on Google.

Ready To Optimize Your Machinery?

When precision matters, waiting costs more than just time—it costs performance, reliability, and revenue. Improper alignment might be costing you more than you realize: higher maintenance, unplanned downtime, and slower production. When your process depends on performance, our alignment services deliver results you can measure.